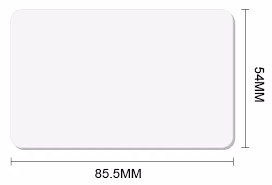

Metal Card Shape

The standard metal card sizes are 85.5 mm x 54 mm (3.3” x 2.2”) – the size of a credit card. Our metal business cards can be made into any size you require.

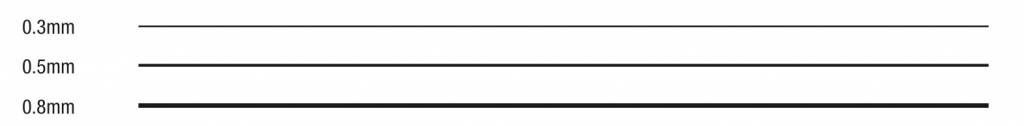

Metal Thickness

Choosing your metal card thickness is as important as your choice of metal, card finish and the actual card design itself. Handing out a business card is often the very first impression someone will get of you or your organization, so it is key to get it right. We have a range of metal card thicknesses available to meet your needs, from 0.3 mm (0.012″) to 0.8mm.

0.3mm

It is the most popular metal card thickness. It is distinctive and unique, yet thin and light with some flexibility.

0.5mm

It is a perfect combination between thin with some flexibility and substance, giving a more premium feel.

0.8mm

It is the thickness of a credit card. Thicker cards are often perceived as premium and luxury; they are a great choice for VIP and membership cards.

Etching

Etching is the technique used to precision-etch custom artwork into the stainless steel card surface. The process etches away unwanted metal, while a photographically prepared mask is used to protect the metal areas that are to remain after the etching process.

Cut Through

When the etching process is used to etch into the same position on the front and back of the card surface, the two areas come into contact and create a unique cut through on the card.

Sequential Numbering & Personalization

Sequential numbering and personalization is ideal for membership cards, invitations, VIP cards or club cards. We will ensure that your cards are numbered or personalized in your nominated numbering range or name list.

Laser Engraving

Used to remove the top layer of the metal card surface, laser engraving is extremely accurate. The laser engraved areas appear in a lighter colour making this process perfect for sequential numbering and personalisation. Unlike etching, laser engraving only removes a thin layer of the material and does not create a deep deboss.